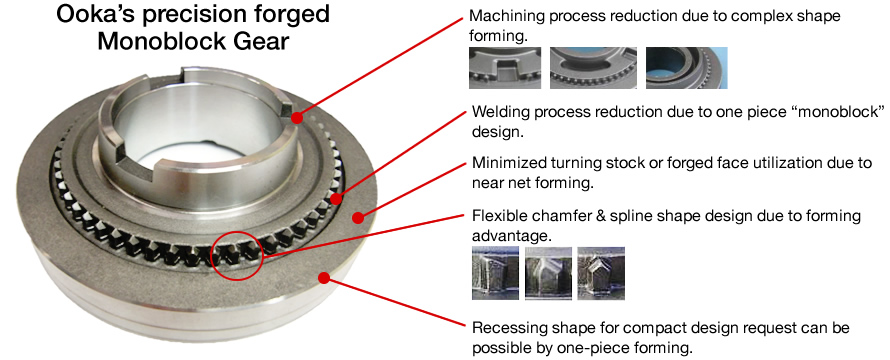

Technical information for Ooka’s precision forged monoblock gear.

- No welding machine shall be invested.

- No more two individual parts management.

- No scrap due to welding deformation issue.

- No scrap due to welding failure

- No scrap due to sputter spreading

- Strength improvement due to one piece design

| Size | Φ80 – 160 |

|---|---|

| Condition | – Machined |

| Chamfer shape | Any |

| Inner spline | Possible |

| Partial tooth thickness adjustment | Possible |

| Synchronizer type | Single – Triple |

| Recessed shape forming | Possible |

| Gear (spline) Accuracy | DIN class 10 |

| Spline Runout | 0.07 max |

| Over 2 balls diameter | ±0.05 |

| Back taper angle | – 6.5°±30’ |

Above data is a reference and each item shall be independently discussed.