Products

There is an ultimate art of precision forging technology that Ooka has reached over a long time period of time.

For EVs/HVs

As the automotive industry is transforming, our various parts made by O-OKA's precision forging technology are used in EVs, which are at the heart of this change.

Sun and Planet Gear

We developed smaller and lighter modules for the Sun and Planetary gear used in powertrain, tailored to meet customer needs.

In addition to helical forging technology, we can provide finished products, including finished tooth surfaces.

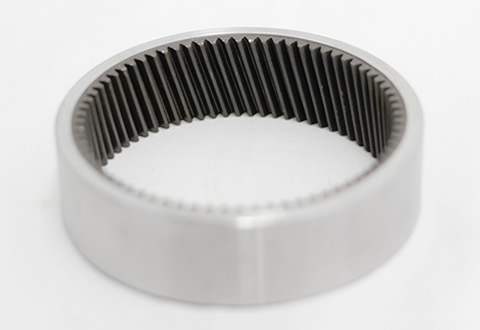

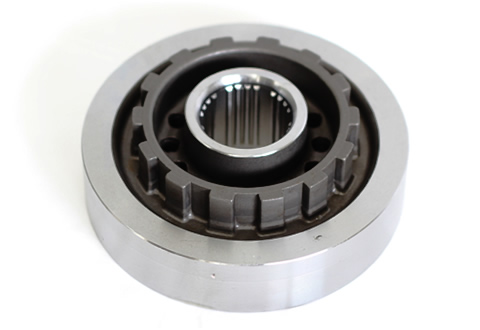

Internal Gear

Compared to conventional helical broaching, shaper and skiving, O-OKA's precision forged internal gear provides smoother and more accurate tooth surfaces, resulting in lower noise.

Additionally, cost and process reductions can be achieved through the use of work hardening in cold forging, without heat treatment.

Parking Gear

Parking gears, which are an essential safety component to protect the driver, are a specialty of O-OKA Precision Forgings. The forging process reliably strengthens gears and improves product quality.

Gear for E-Bike

We can forge complex ratchet shapes in a single shot, helping to reduce costs.

We also offer shapes that require minimal machine allowance for post-processing.